Workshop Pit Upgrade, Repair & Refurbishment

Hartex Engineering also offers a number of solutions to upgrade your old pit and turn it into a modern well-equipped prefabricated pit complete with a heavy vehicle jacking system which can cater for the wheel base of your whole fleet without the old fashioned bridgehead that was previously required.

Workshop Pit Fit-Out

All of Hartex’s Pit depths are made to the new RMS standards.

Upgrade Features

- Quick to install on site

- No costly form work or pre-concrete works by the builder

- Minimal down time to your existing workshop pit activities

- Access stairs and safety handrails

- Jacking rails to support pit jacks and beams

- 2 pack epoxy is painted on external surfaces offers maximum protection against corrosion

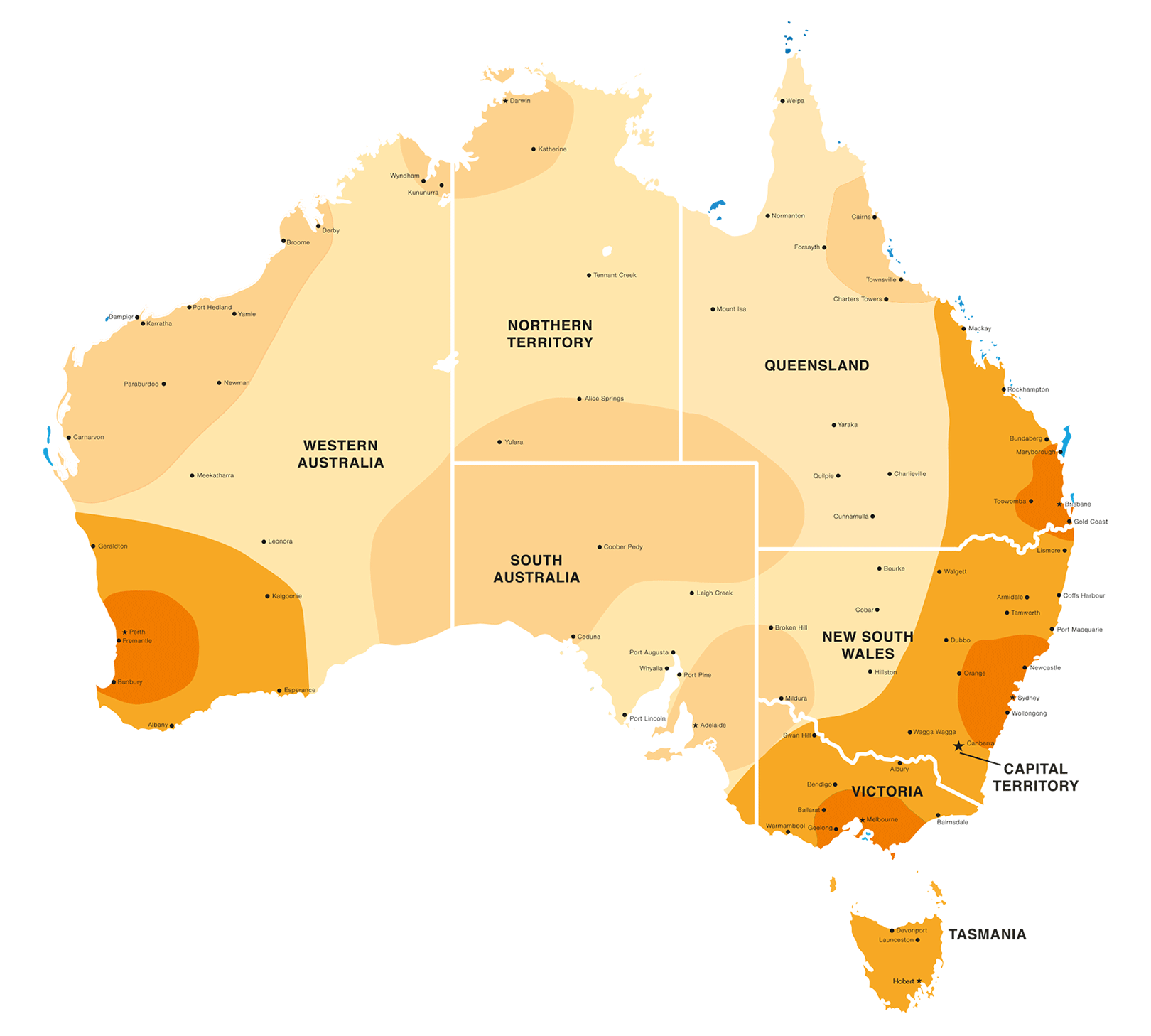

ZERO EMISSIONS (ZEB) Bus Service Pit Upgrades

With the rollout of ZEBuses, Hartex are leading the way with innovative equipment and customised design to ensure the new range of ZEB’s can be serviced and maintained efficiently to Australian standards

ZEB Pit Fit Out Options:

- In-ground Lifts for lift at axle, chassis or wheel

- Roller Brake & Suspension Testers

- Roof Access Platforms for accessing batteries and air con systems

- Workshop Pit Lighting class 1 zone 2

- Lubrication systems – Engine Oil, Differential Oil, Hydraulic Oil, Coolant Oil, Greases etc

- Waste oil and coolant removal system

- Automated Pit Safety Covers

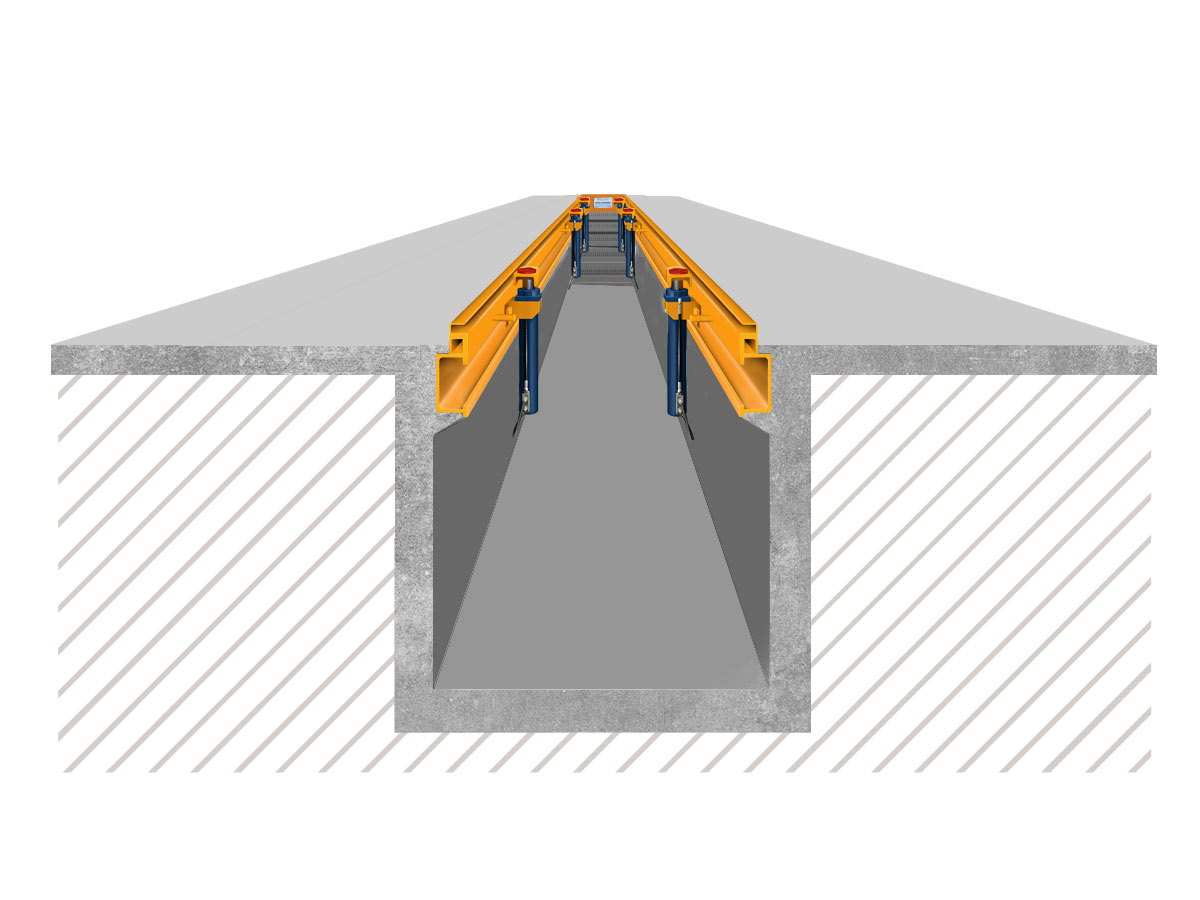

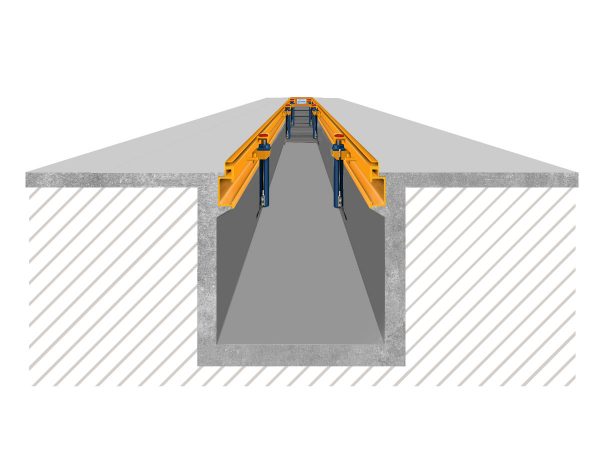

Inground Jacking System

In-ground lifts provide clear access to the underbody electrical charging devices and drive motors on axles. Lift at axle, chassis or wheel options for easy removal of electric motors.

Roof Access Platforms

ZEBuses need regular and safe access to the roof for accessing battery and air conditioning systems. We have the most extensive range of roof access systems including our patented gap compensation systems that close the gap between the fixed and moving parts of the plaform.