Description

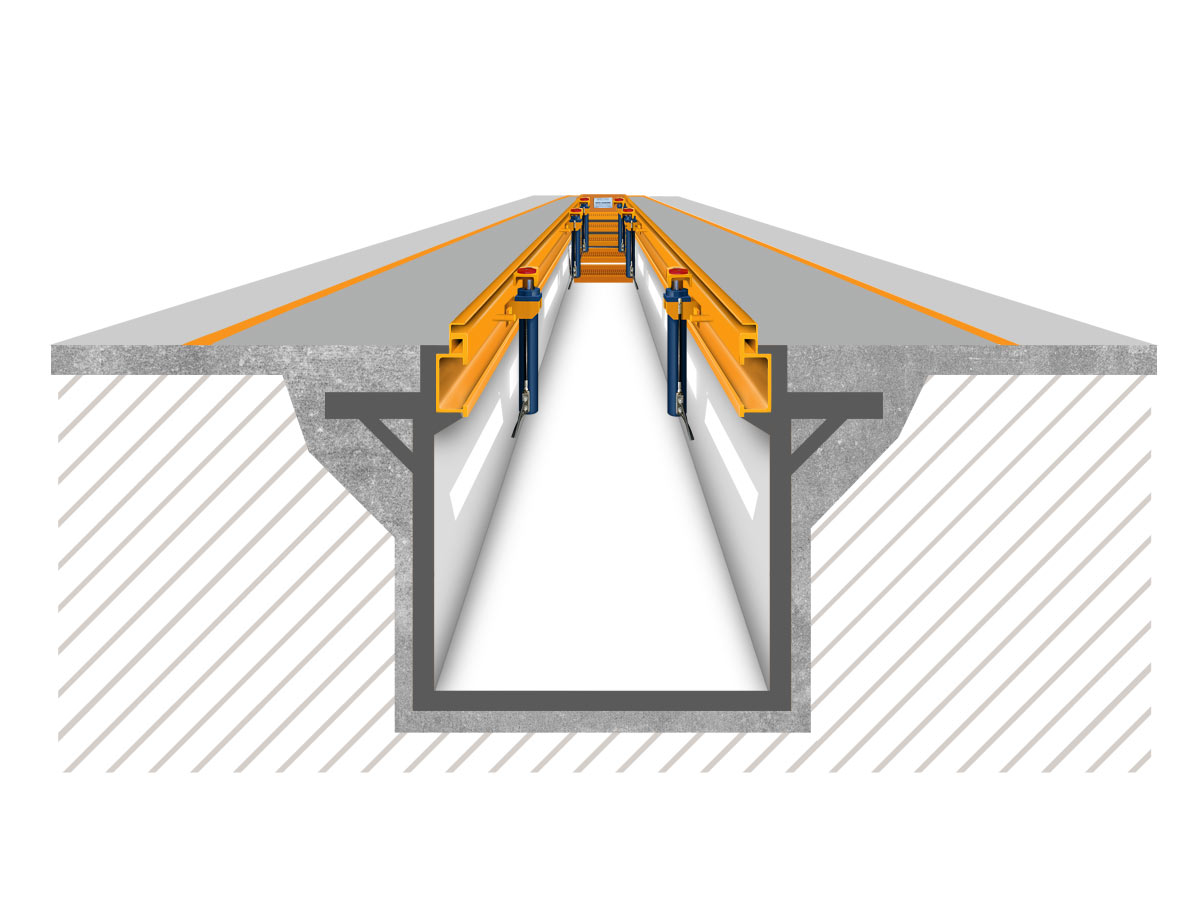

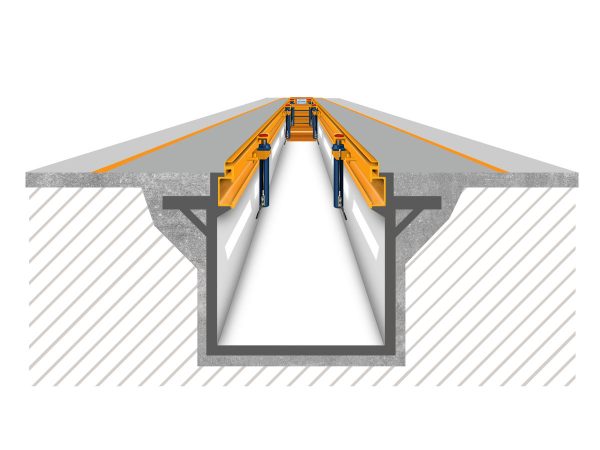

Prefabricated ‘Drop-in’ Truck & Bus Service Pits

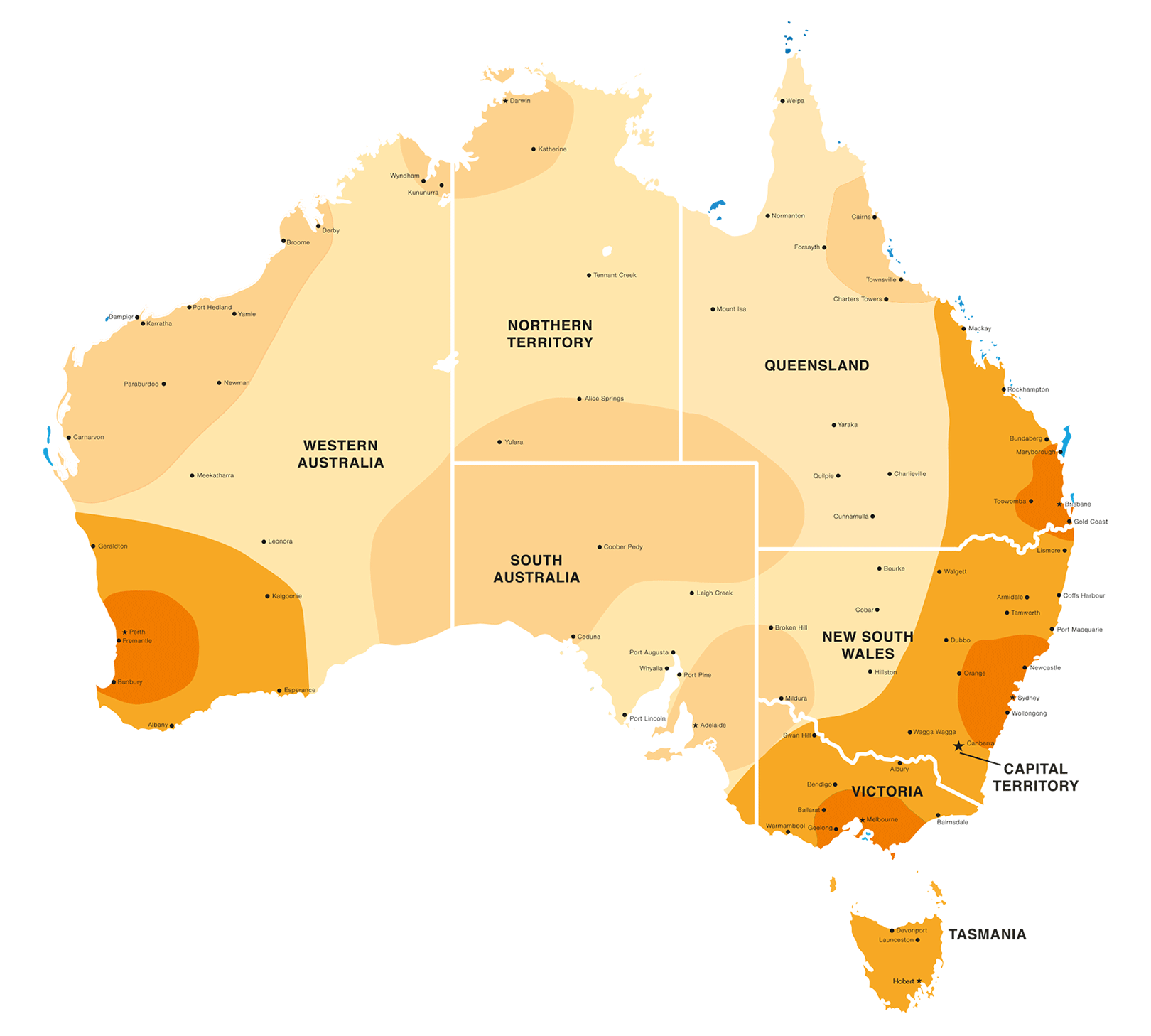

It is because of our extensive experience in delivering turnkey solutions like this, that our clients trust Hartex Engineering to deliver these complex pre-fabricated pit systems. This after all is too risky a venture to contract an inexperienced company with little or no demonstrated evidence of doing this type of work. We highly recommend you seek references of similar jobs that your potential service pit builder is promising you. We stand by our products, which is why the Hartex drop in pit system has become the industry benchmark in Australia and our rapidly expanding international markets.

When configured as a truck service pit, we can custom build Hartex drop in pits to bay lengths of 6 to 40m long, catering to small truck fleets, B-doubles and road trains. Our prefabricated pit systems can also be configured to a large variety of bus fleets and inspection stations like those operated by TMR (Transport Main Roads – QLD ) and RMS (Roads and Maritime Services – NSW).

Prefabricated Pit Inclusions

Prefab Pit fit-out options:

- Roller Brake & Suspension Testers

- Heavy Vehicle Jacking Systems

- Workshop Pit Lighting class 1 zone 2

- Pit Ventilation with interlocked Service Pit Ventilation which is required for hazardous area zoning compliance

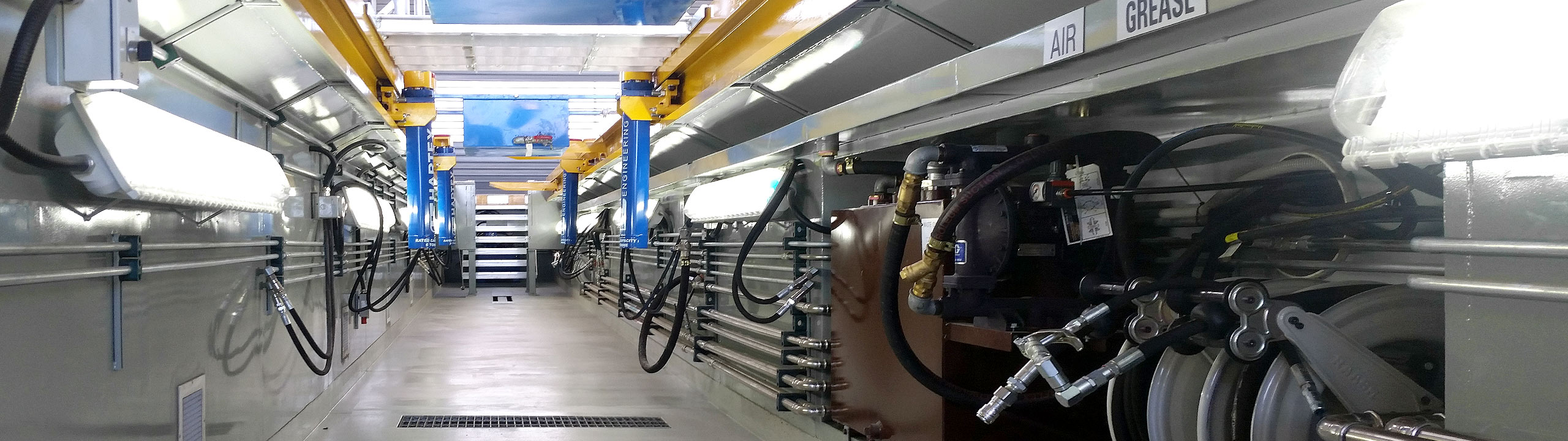

- Lubrication systems – Engine Oil, Differential Oil, Hydraulic Oil, Coolant Oil, Greases etc

- Waste oil and coolant removal system

- Automated Pit Safety Covers

Diagnostic Equipment

Prefabricated pits can be pre-fitted with roller brake testers, suspension testers and shaker plates.

Hartex Pit Jacking System

The Hartex pit jacks pictured are catered to suit the specific needs of your fleet and is yet another innovation by Hartex to make the service pit environment safer and more productive. Check out our complete range of Pit Jacks to find a jacking system that suits your work or fleet.

Lubrication Equipment

Lubrication range includes.

Side Access Tunnels

Hartex drop in pit systems can also be designed with side access tunnels. Many truck service pits and bus service pits are too short for the types of vehicles being serviced on them. It is mandatory under the OH&S act to have a clear path of entry and exit for a mechanic working in a pit in the event they are injured or a rescue is to be mounted due to other emergencies like smoke or fire events.

Pit Lighting & Ventilation

Providing your pit with a good lighting and ventilation system is paramount in order to ensure a safe working environment for your mechanics. The hazardous environment standards AS/NZS 60079 classifies service pits as class 1 zone 2 environments PROVIDED they are mechanically ventilated such that a minimum of 6 air changes distributed evenly across the length of the pit is achieved.

A Complete Turnkey Solution for Heavy Vehicle Workshops

Delivery & Installation

Our prefab pit systems are fabricated off-site at our Sydney manufacturing plant. The pit arrives on site complete and is dropped into position.

25 Year Structural Warranty

Made to Australian standards our workshop pits and service bays come with a 25 year structural warranty, making Hartex pits the most durable long lasting pits in the world.

Service & Support

Our locally based engineering experts can provide programmed and event based maintenance that includes priority on-site support for platinum service customers.